Ceramic flat sheet membrane

Category:

DESCRIPTION

Technical Parameter

| Membrane type | Flat membrane |

| Filtering method | External inlet and internal suction filtration method |

| Material | Ceramic part:Al203 |

| Nominal pore size | ≤ 0.1 μm |

| Standard membrane size | H×W×T=1046×250×6 mm |

| Membrane weight (dry/wet) | 2.2/4.5 kg |

| singke membrane filtration area | 0.5 m2 |

| Pure water permeability | 60 m3/(m2·d)(100 kPa, 25℃) |

| porosity | ≥ 42% |

| Tolerance pH range | 2 ~12 |

| Maximum service temperature | 80℃ |

| Tolerance transmembrane pressure range | ± 80 kPa |

Membrane component specifications

| Model | HY-M25-U1 | HY-M50-U1 | HY-M200-U1 | HY-M200-U2 |

| Number of membrane (pieces) | 25 | 50 | 200 | 400 |

| Effective membrane area ( m2) | 12.5 | 25 | 100 | 200 |

| Module frame size W × D × H(mm) | 650×370×1750 | 1050×370×1750 | 2200×780×1750 | 2200×780×3300 |

| Module frame material | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Single module dry/wet weight | 120/180kg | 204/319kg | 631/831kg | 1209/1609kg |

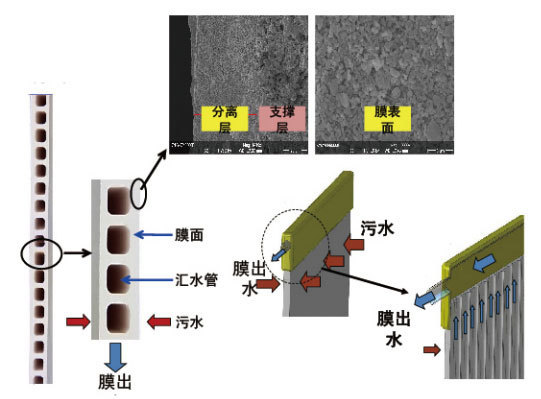

Membrane structure and filtration method

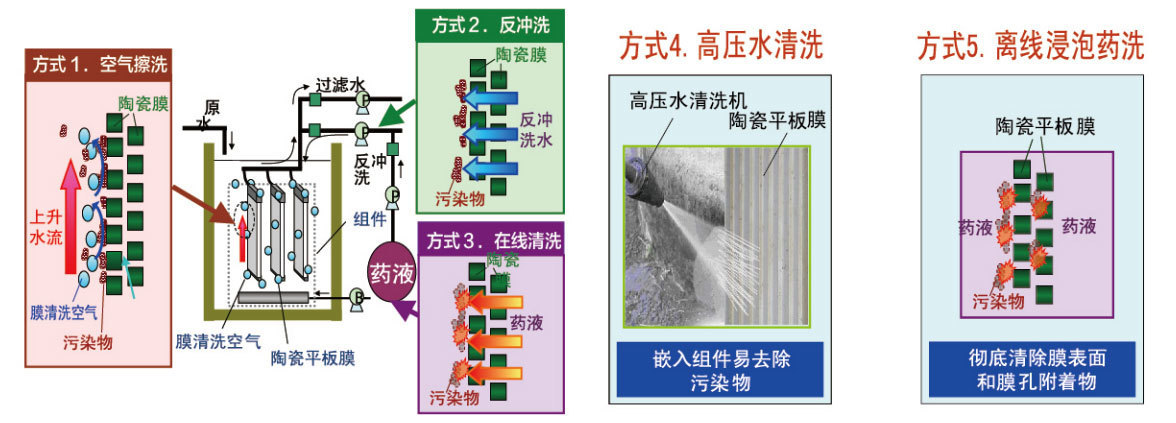

Cleaning method of membrane

Functional nano ceramic flat film

Compared with traditional separation media, flat Ceramic membrane has the following advantages:

|

Long service life ● Under normal conditions, the service life can reach over 20 years. High operating flux ● Under MBR conditions, the stable operating flux is higher than 30LMH. Strong pollution resistance ● Strong anti pollution ability and good membrane regeneration performance. |

Easy to install and maintain ● Modular structure, convenient system installation and maintenance. Excellent physical and chemical performance ● Good chemical stability, high mechanical strength, acid alkali resistance, and corrosion resistance. |

Comparison of performance with other materials

| Membrane type | Nano ceramic flat film | Organic flat film | Hollow fiber | Explanation of the advantages of nano ceramic flat film |

| Membrane pore size | 0.1μm | 0.1μm | 0.1μm | Narrow and uniform pore size distribution range |

| Main materials | Al203、TiO2、ZrO | PVDF、PE | PVDF | High-temperature calcination |

| Operating flux | 30~150 LMH | 15~30 LMH | 12~18 LMH | Flux 3-8 times |

| General status Transmembrane pressure difference |

Lower 10~30kPa | Lower 10~30kPa | Higher 30~50kPa | Low and stable |

| Drug washing cycle | Online: 15~30 days/time Offline: 36 months/time or more |

Online: 5~7 days/time Offline: December/time |

Online: 1~7 days/time Offline: March June/time |

Long drug washing cycle |

| Clean | Multiple cleaning methods and good results | Few cleaning methods and poor effectiveness | Few cleaning methods and poor effectiveness | Easy to clean and recover |

| Service life | 15~20 years | 3~5 years | 3~5 years | 4~5 times the lifespan |

| Mechanical strength | Tall | Same as | Easy to break wire | Not easily damaged |

| Stain resistance | Good hydrophilicity | Same as | General, easily tangled fibers | Strong pollution resistance |

| Maintenance operations | Fully automatic backwashing Fully automatic online medicine washing Scrubbable surface |

Generally not backwashable | Poor backwashing effect | Convenient operation |

| Recycling | Can be used as a raw material Direct recycling |

Hazardous waste | Hazardous waste | Environmentally friendly |

Welcome to your message for consultation